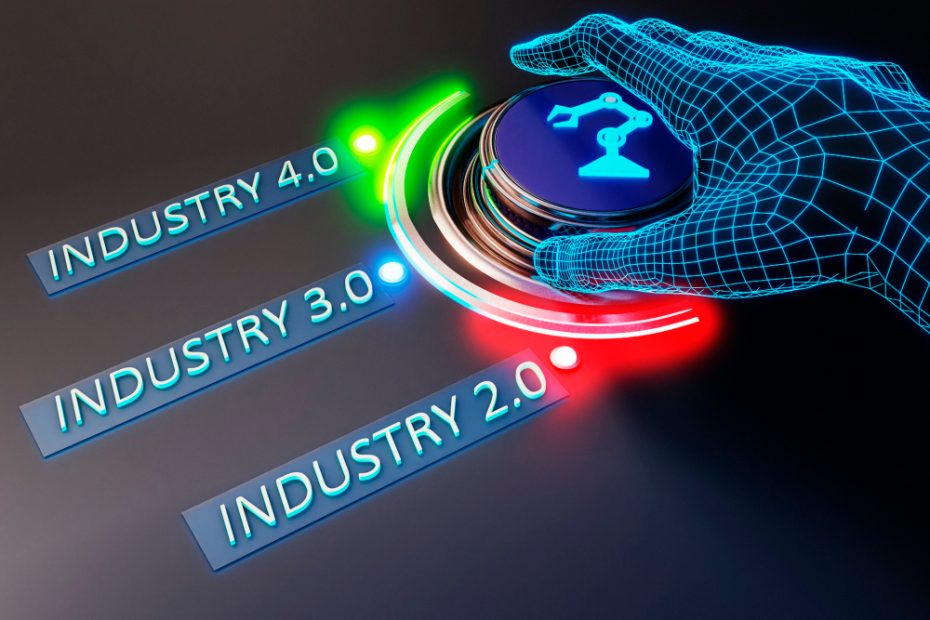

The evolution of industrial technology has witnessed several significant shifts, and two of the most prominent phases are Industry 4.0 and Industry 5.0. These terms represent critical milestones in the development of manufacturing and industry, each bringing its own set of advancements and paradigms. In this comparative analysis, we will delve into the key differences between Industry 4.0 and the emerging Industry 5.0, exploring how they shape the future of production, technology, and human-machine collaboration.

Industry 4.0: The Foundation of Automation

Industry 4.0, often referred to as the Fourth Industrial Revolution, is characterized by the widespread adoption of automation, data exchange, and the Internet of Things (IoT) in manufacturing. Here are some key features of Industry 4.0:

1. Automation and Connectivity:Industry 4.0 focuses on the automation of production processes and the seamless connectivity of machines, systems, and products. It emphasizes efficiency and precision in manufacturing.

2. Big Data and Analytics: The collection and analysis of vast amounts of data from machines and sensors enable predictive maintenance, process optimization, and data-driven decision-making.

3. Human-Machine Collaboration: While automation is central, human workers are still integral to the process, working alongside machines in a complementary manner.

4. Digital Twins: The concept of digital twins involves creating virtual replicas of physical objects, allowing for real-time monitoring, analysis, and simulations.

Industry 5.0: The Human-Centric Evolution

Industry 5.0 represents a departure from the purely automated and data-driven approach of its predecessor. It introduces a more human-centric perspective to manufacturing and industry. Here are the distinguishing features of Industry 5.0:

1. Collaborative Robotics: Industry 5.0 places a strong emphasis on collaborative robots, or cobots, working alongside human workers in shared spaces. These cobots are designed to be safe, easy to program, and adaptable.

2. Skill Enhancement: Instead of replacing human workers, Industry 5.0 aims to enhance their skills and capabilities. Workers are empowered to work in collaboration with cobots, leveraging their strengths.

3. Customization and Flexibility: Industry 5.0 prioritizes the ability to produce customized, small-batch, and flexible products efficiently. This contrasts with the mass production focus of Industry 4.0.

4. Decentralized Decision-Making: In Industry 5.0, decision-making is distributed, allowing individual machines and systems to make autonomous choices based on real-time data, enhancing agility.

5. Human-Centered Design: The design of manufacturing systems in Industry 5.0 is guided by a human-centered approach, considering ergonomic factors and the well-being of workers.

Comparative Analysis

– Automation vs. Collaboration:

Industry 4.0 leans heavily towards automation, while Industry 5.0 emphasizes collaboration between humans and machines.

– Mass Production vs. Customization:

Industry 4.0 is more geared toward mass production and efficiency, whereas Industry 5.0 prioritizes customization and flexibility.

– Data-Driven vs. Decentralized:

Industry 4.0 relies on centralized data analysis, while Industry 5.0 incorporates decentralized decision-making by machines.

– Efficiency vs. Agility:

Industry 4.0 emphasizes efficiency and optimization, while Industry 5.0 focuses on agility, adaptability, and responsiveness to changes.

– Human Augmentation vs. Replacement:

Industry 4.0 introduces technology to augment human capabilities, whereas Industry 5.0 seeks to enhance and empower human workers in a collaborative setting.

In the ongoing evolution of industry, both Industry 4.0 and Industry 5.0 have their unique strengths and contributions. While Industry 4.0 paved the way for automation and data-driven decision-making, Industry 5.0 takes a bold step forward by prioritizing collaboration, customization, and human-centric design. The comparative analysis shows that Industry 5.0 doesn’t replace Industry 4.0 but rather builds upon its foundations, offering a new perspective on how manufacturing and industry can evolve to better serve both businesses and workers. The choice between the two depends on a company’s goals, industry, and commitment to embracing the future of work.